J-Magnetics-A reliable magnetic separation equipment solution provider!

Contact :Joshua Shen

Email: joshua@j-magnetics.com

Add: Yueyang Tower District, Yueyang City, Hunan Province, China.

Eddy Current Separator

EDDY CURRENT SEPARATOR

Separate aluminum & other non-ferrous metals from your process stream, municipal recycling facility (MRF) municipal solid waste facility (MSW), scrap residue and other recyclables with KMD’s eddy current separation equipment.

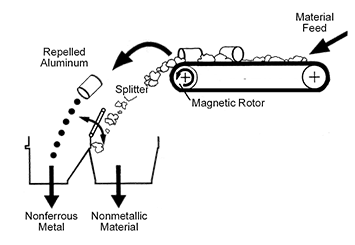

How eddy current separation works:

Eddy current separation is based on the use of a magnetic rotor with alternating polarity, spinning rapidly inside a non-metallic drum driven by a conveyor belt. As non-ferrous metals pass over the drum, the alternating magnetic field creates eddy currents in the non-ferrous metal particles repelling the material away from the conveyor. While other materials drop off at the end of the conveyor, the non-ferrous metals are propelled forward over a splitter for separation.

KMD's eddy current separation equipment can be used to remove non-ferrous metals from municipal solid waste, auto shredding residue operations, glass cullet, electronic scrap, UBC reclamation, etc.

Uses

Separate aluminum & other non-ferrous metals from process stream, municipal recycling facility (MRF) municipal solid waste facility (MSW), scrap residue and other recyclables.

Advice to User:

1.For even, stable and level material layer on the belt, vibratory feeder is the better choice.

2. It will be more efficient for metals with particle size over 25mm2 .

3. Fixed and firm installation base required due to assembled internal high-speed-rotation parts assembled which causes strong vibration during operation.

4.Please do keep the easily-magnetized objects off the separator’s working area due to the strong alternating magnetic field.

5.Rotation speed can be adjusted via variable frequency controller.

6. If raw materials contain tramp irons, a magnetic separator is recommended.

Technical Parameters

Model | Belt Width(mm) | Driving Motor(kw) | Handling Capacity(m3/h) | Overall Dimensions (mm) A×B×C | Weight(kg) |

EC-60 | 650 | 4.0 | 6 | 2250×1750×1075 | 1100 |

EC-80 | 800 | 5.5 | 7.5 | 2360×1960×1110 | 1200 |

EC-100 | 1000 | 5.5 | 9 | 2470×2200×1140 | 1400 |

EC-120 | 1200 | 7.5 | 12 | 2560×2450×1180 | 1500 |

To see what our valued customers said: